Pharmaceuticals and cosmetics often contain fat-soluble active ingredients. For example, fat-soluble vitamin A is essential to maintaining eye health. Vitamin A is known to promote the production of mucin and hyaluronic acid, which, respectively, are necessary to stabilize tear fluid and repair tissue damage.1-3 In Lion’s over-the-counter (OTC) eye drops, vitamin A is dispersed in a nanoemulsion as droplets of 100 nm or smaller. Working within established limits on the types and quantities of surfactants that can be used in such products, Lion’s research investigates the structures and function control of nanoemulsions as drug delivery systems in order to maximize the efficacy of vitamin A.

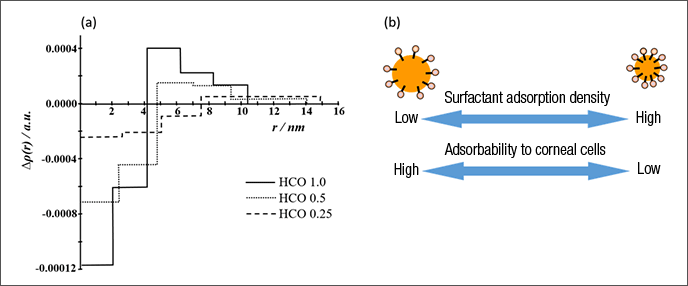

To ensure that the vitamin A contained in the eye drops reaches the corneal cells, the nanoemulsion droplets must firmly adsorb to the surface of the eye, so that they are not flushed away by tears. Given this, we performed a structural analysis to determine the nanoemulsion structure that would result in maximum vitamin A adsorption. Using small-angle X-ray scattering, we conducted electron-density distribution analysis of the nanoemulsion droplets. This yielded the novel finding that the emulsions with the highest adsorbability were those in which the adsorption density of the surfactant molecules surrounding the vitamin A was low, leaving the surface of the vitamin A partially exposed (Figure 1).4

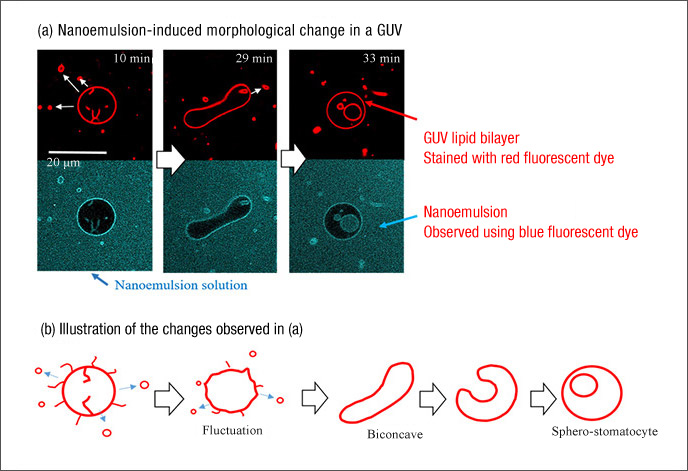

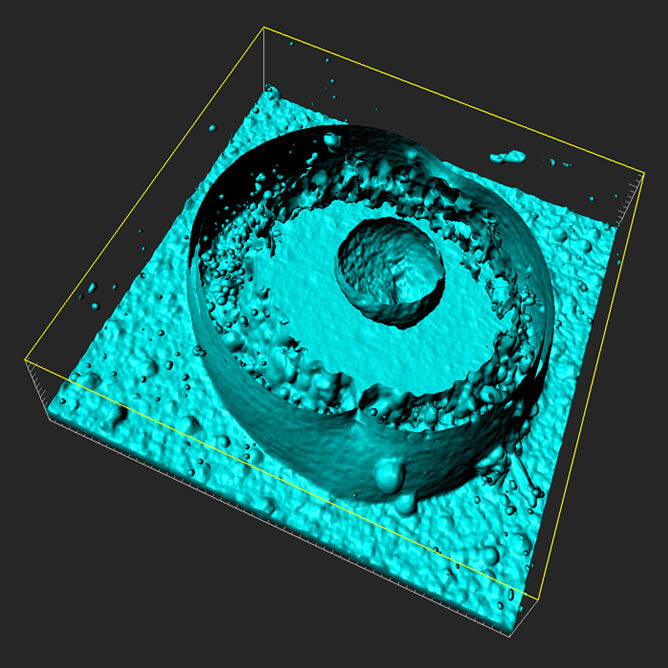

To increase its efficacy, vitamin A must be able to cross the cell membrane and enter corneal cells, where it can be bioactive. We succeeded in preparing a nanoemulsion that triples the efficacy of vitamin A by changing the surfactant used for emulsification. To better understand the mechanism by which vitamin A permeates cells, we used cell membrane-mimicking giant unilamellar vesicles (GUVs), observing the changes to their lipid bilayer induced by the interaction of a nanoemulsion over time.5 Due to the action of the nanoemulsion, an endocytic morphological change occurred in which the lipid bilayer of the GUV formed an internal vesicle (Figure 2).

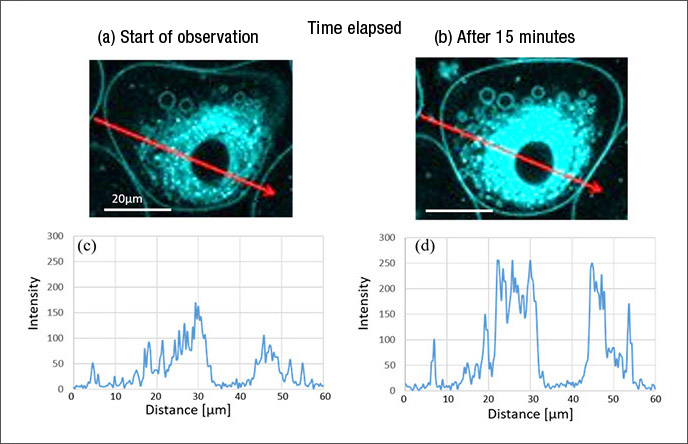

To test if this change could occur in an actual cell, we introduced a nanoemulsion containing vitamin A marked with a fluorescent dye to corneal cells. We found that endocytosis occurred in the cells to which the vitamin A in the nanoemulsion had adsorbed onto the cellular membrane, with the vitamin A in vesicles being brought into the cell and delivered to the cell nucleus (Figure 3).5

By this mechanism, nanoemulsions effectively permeate cells. Specifically, a nanoemulsion containing 50,000 units of vitamin A on a formulation basis has successfully achieved an effect equivalent to that observed in another formula containing 150,000 units. This effect-boosting mechanism is being applied in high-permeation eye drops.

1) Y. Kubo, et al., J. Jpn. Ophthalmological Soc. (Nippon Ganka Gakkai

Zasshi.) 103 (8), 580–583 (1999)

2) H. Toshida, et al., J. Nutr. Sci. Vitaminol. 58, 223–229 (2012)

3) H. Toshida, et al., Curr. Eye Res. 33, 13–18 (2008)

4) M. Matsuki, et al., Journal of Oleo Science , 63(9), 903-909 (2014)

5) M. Miyake, et al., Colloids and Surfaces B: Biointerfaces, 169, 444-452 (2018)

6) M. Kurioka, M. Miyake, et al., 33rd Annual Meeting of the Japan Society of Drug Delivery System

(2017)

Rinse-free washing technology incorporated into Acron Smart Care, a laundry detergent (for delicates) with Fabric-softening agents a built-in softening agent

Nano-Washing Verified Using Small-Angle X-Ray Scattering

Applying Biointerface Research to Maximize Active Ingredient Effectiveness

Using Aggregate Control Technology to Enhance Product Functions

Related Information