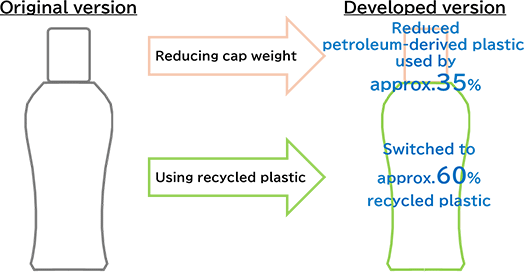

Lion Corporation (Representative Director, President and Executive Officer: Masayuki Takemori) has received a WorldStar Award in the Household Category at the WorldStar Contest 2025, for the bottle design it jointly developed with Mebius Packaging Co., Ltd. (President: Takashi Iida) for SOFLAN Premium Deodorizer, a fabric softener. This award, organized by the World Packaging Organisation (WPO), recognizes the development of technology geared toward controlling the physical properties of plastic by enabling used plastic beverage bottle caps to be converted into a material suitable for reuse in bottle molding, specifically, as recycled plastic for molding the main bottle. In addition, the amount of petroleum-derived plastic use has been reduced by incorporating recycled materials and creating a more lightweight cap for the product bottle, resulting in an environmentally friendly packaging solution. The awards ceremony was held in Milan, Italy, on Friday, May 30, 2025.

■About the WorldStar Contest 2025

The WorldStar Contest is an international packaging competition organized annually by the World Packaging Organisation with the aim of promoting the development and adoption of outstanding packaging design and technology. Only exemplary products that have received recognition at the national level are eligible for entry in this prestigious contest, with the SOFLAN Premium Deodorizer bottle earning its eligibility by winning the Japan Star Award at the 2024 Japan Packaging Contest. This year saw 550 entries from around the world, with entries evaluated by over 50 judges on eight criteria such as protectiveness, usability and environmental considerations.

■Research Background

Lion has established a target for 2030 of achieving at least a 70% reduction in petroleum-derived plastics used in its products and packaging as part of its goal to realize a resource-circulating society (LION Eco Challenge 2050). In line with this, we have newly developed an environmentally conscious bottle created from such resources as used plastic beverage bottle caps (hereinafter referred to as “beverage caps”), a material we have adopted for the main bottle of our fabric softener.

■Development Policy

When making recycled plastic-based products, it is necessary to flexibly consider the range of materials available to ensure reliable procurement. Therefore, we focused our efforts on beverage caps, which, despite posing challenges for use in bottle molding, can be reliably procured. This is what led us to adopt them as the main plastic resource for the product’s main bottle.

■Technical Features

Beverage caps collected from the market are characterized by their ability to be treated as high-quality recycled plastic, meeting three key requirements: 1. safety (compliance with the Food Sanitation Act); 2. quality (free from odors and foreign material); and 3. supply stability (ensuring stable raw material procurement).

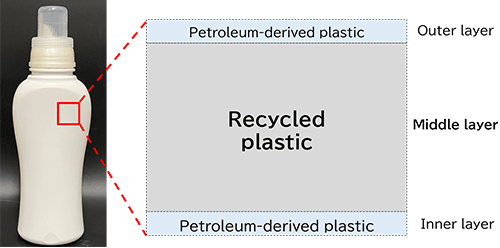

However, being made from plastic optimized for cap molding, beverage caps are less suitable as a resource for bottles themselves, making their utilization at high mixing ratios difficult. To address this, we developed a technology that incorporates other types of recycled plastic more suitable for bottle molding as a method to control the material’s properties.

These achievements were recognized with a WorldStar Award in the Household Category at the WorldStar Contest 2025.

■Comments from the Developer on Receiving the Award

As part of our efforts to achieve the long-term environmental objectives laid out in “LION Eco Challenge 2050”, we focus daily on increasing the use of sustainable materials in our development projects. For this bottle, we started by identifying suitable recycled materials then evaluated them comprehensively from both the supply and quality perspectives. Going forward, we will continue our efforts to develop environmentally friendly packaging.

SOFLAN Premium Deodorizer Brand Site (Japanese)

https://soflan.lion.co.jp/soflan/

■Future Outlook

・Increasing recycled plastic use

While the main product bottle is made using over 60% recycled plastic, we will continue our efforts toward achieving a recycled plastic usage rate of 100% in the future.

・Application to other products

We will continue exploring ways to extend this technology to other products made from similar materials.

Lion will continue its efforts to advance technological development aimed at reducing the environmental impact of its packaging and containers. We are committed to achieving our 2030 target of a reduction of at least 70% in the use of petroleum-derived plastics, as outlined in the “LION Eco Challenge 2050”, and to contributing to the realization of a resource-circulating society.

【Related Information】

◆Long-term environmental objectives “LION Eco Challenge 2050”

https://www.lion.co.jp/en/sustainability/env/#eco-challenge-2050