Lion Corporation (Representative Director, President and Executive Officer: Masayuki Takemori) and Toyo Ink Co., Ltd. (President: Hideki Yasuda) jointly developed the LOOK Plus Bath Cleansing Clear Citrus Fragrance Large Refill Pack (launched in November 2024), which has received the Director-General for GX Promotion, Ministry of Economy, Trade and Industry Award, one of the top JAPAN STAR awards at the JAPAN PACKAGING CONTEST 2025 organized by the Japan Packaging Institute. The ceremony for the JAPAN STAR awards was held on Wednesday, August 27, 2025, at the Tokyo Garden Palace hotel. Earlier this year, this product also received the 49th Kinoshita Prize in the R&D Category from the Japan Packaging Institute.

The award ceremony

■About the JAPAN PACKAGING CONTEST 2025

Organized by the Japan Packaging Institute, the JAPAN PACKAGING CONTEST has been held since 1967—the 2025 event marks its 47th iteration—with the aim of promoting the development and dissemination of packaging and related technologies that respond to the needs of the times and society while also enriching lifestyles . Judges review the actual products firsthand, assessing them from every perspective, including materials, design, technology and environmental responsiveness, before selecting winners for the top JAPAN STAR awards, the Packaging Technology Award, and the Packaging Category Award. This year, 12 JAPAN STAR awards, 6 Packaging Technology Awards, and 13 Packaging Category Awards were presented.

Winning entries qualify for the “WorldStar Contest” organized by the World Packaging Organisation , which brings together award-winning works from around the world.

■Research Background

Aiming to realize a resource-circulating society, Lion is looking toward 2050 as it works to address challenges with the goals of minimizing the use of plastics and ensuring that all plastics used are collected and recycled. Among our products, refill packs, our main form of packaging, are produced using laminated films that combine various materials to meet required container performance specifications. However, separating the various materials from these laminated films for recovery as high-purity single materials is difficult and one of the factors that hinders packaging recycling. To address this, Lion collaborated with Toyo Ink Co., Ltd. to develop a debondable adhesive that enables the laminated layers to be separated more easily post consumption, with the goal of putting into practical use refill packs that offer enhanced recyclability.

■Technical Features

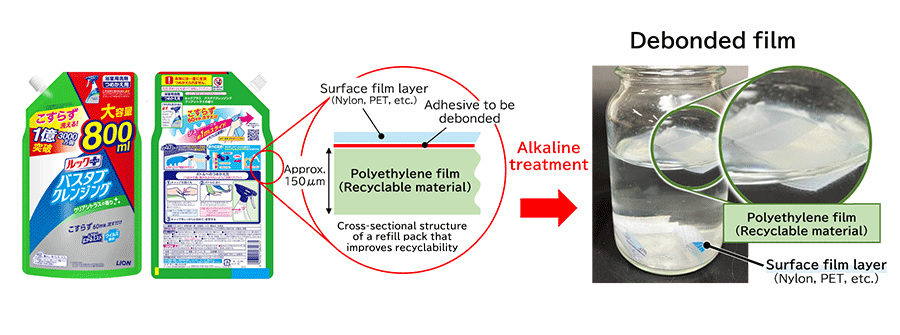

With the introduction of a debondable adhesive that dissolves under specified conditions for lamination, we have, for the first time, adopted and put into practical use a “delamination recycling technology” that enables the efficient recovery of recyclable single materials from laminated films. The laminated film developed with this technology separates into a "polyethylene film" (consisting of a single material) and an "outer film layer" (composed of materials such as nylon or PET) when stirred in an alkaline aqueous solution under specific conditions. Due to differences in relative density, only the polyethylene film floats on water, making it easy to collect for use as a recyclable material (Figure 1). Furthermore, to preserve the essential functions of existing refill packs—such as content protection and impact resistance—the design incorporates measures to prevent interlayer delamination during detergent use. As a result, while the films can be easily delaminated during recycling, sufficient delamination resistance is ensured during the sales and use stages of the product life cycle.

This award recognized the product for its environmental consideration in enabling the efficient recovery of recyclable polyethylene film while maintaining the quality of containers made with multiple materials.

Fig.1 Layer structure of the product using debondable adhesive and delamination separation technology

■Future Outlook

To achieve the level of plastic resource circulation we aim for requires collaboration with a wide range of stakeholders. With this technology as well, we will work together with various manufacturers and recycling contractors to expand the use of recyclable products and support the establishment of recycling processes, targeting the standardization of these technologies and embedding them into social systems.

■Comments from the Developer on Receiving the Award

In pursuit of our long-term environmental objectives as embodied in the “LION Eco Challenge 2050”*1, we are working to develop refill packs—which account for a large proportion of our product packaging—as a resource for circulation, not only by improving our own packaging design technologies but also by incorporating outstanding technologies from other companies. In the development of this product, Lion worked in collaboration with Toyo Ink, conducting repeated rounds of issue identification and product improvement from early-stage performance evaluations through to ensuring production suitability that ultimately led to commercialization. Looking ahead, we will further advance the circulation of refill packs made with this technology and continue to develop packaging with consideration for the environment.

*1 Long-term environmental objectives “LION Eco Challenge 2050” https://www.lion.co.jp/en/sustainability/environment/#eco-challenge-2050

LOOK Plus Bath Cleansing Brand Site (Japanese) https://look.lion.co.jp/lookplus/bathtub/

【Related Information】

The Lion Group Sustainability Material Issues and Objectives for 2030

Lion’s SDG-Related Initiatives

Lion’s Sustainability

Lion has commercialized refill packs with improved recyclability (Japanese)