One household chore consumers regard as being particularly onerous, physically and mentally, is cleaning the bathtub. With the idea of making cleaning the tub less burdensome, Lion developed LOOK Plus Bath Cleansing. With this product, the user simply mists the tub, waits 60 seconds and then rinses it off, cleaning the entire bath with no scrubbing. For the creation of this product, in addition to formulating a spray with the detergency to remove grime without scrubbing, it was essential to develop a spray bottle capable of evenly applying the mist to the entire tub. Lion’s researchers considered various types of containers before ultimately developing a new misting trigger spray bottle.

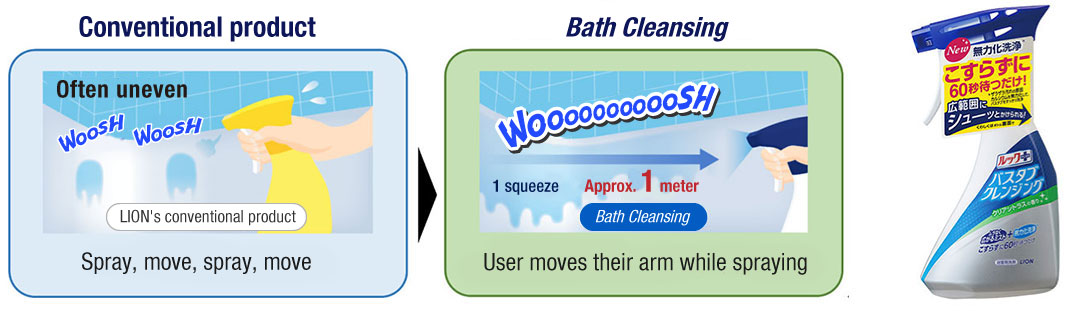

With a conventional trigger spray bottle, applying a detergent to an entire bathtub requires spraying, re-aiming and spraying again and again. Furthermore, because such bottles concentrate the spray in a relatively small area, the application is often uneven. In contrast, an aerosol spray can allows for a longer, continuous spray, helping avoid uneven application, but is not ideal for a bath detergent as it cannot be refilled. To solve this problem, Lion’s researchers reengineered the structure of a conventional spray bottle trigger, developing a new trigger that can produce a long, continuous spray, similar to that of an aerosol can. During development, care was also taken to ensure ease of use by, for example, lengthening the trigger. This new trigger design received the Technical Packaging Award in the Japan Packaging Institute’s 43rd annual Kinoshita Awards, the most prestigious packaging technology awards in Japan.

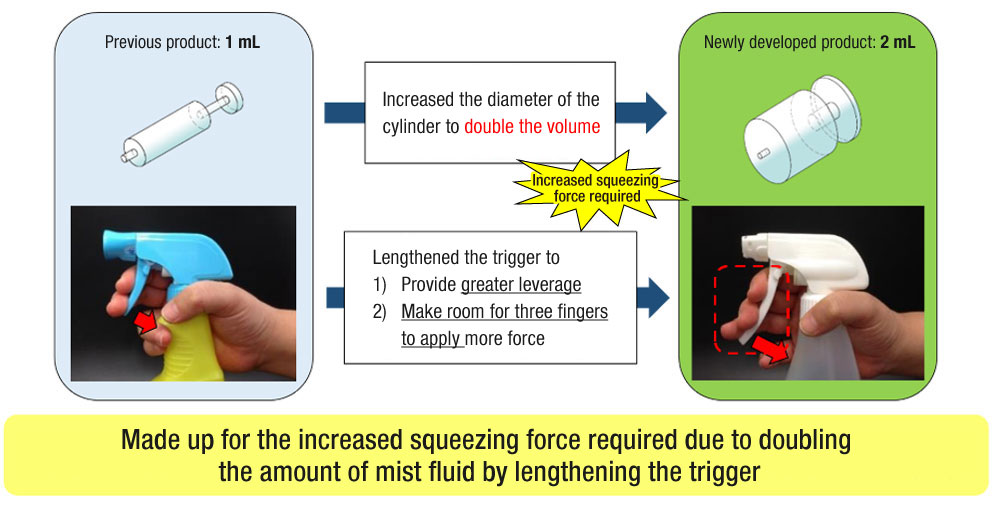

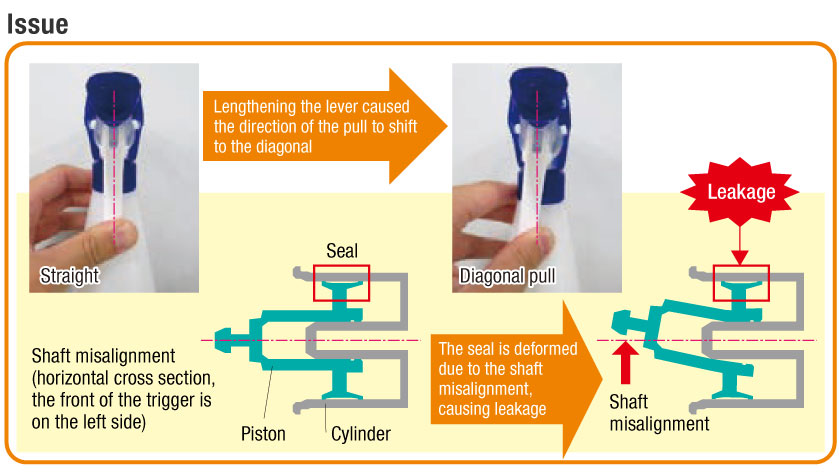

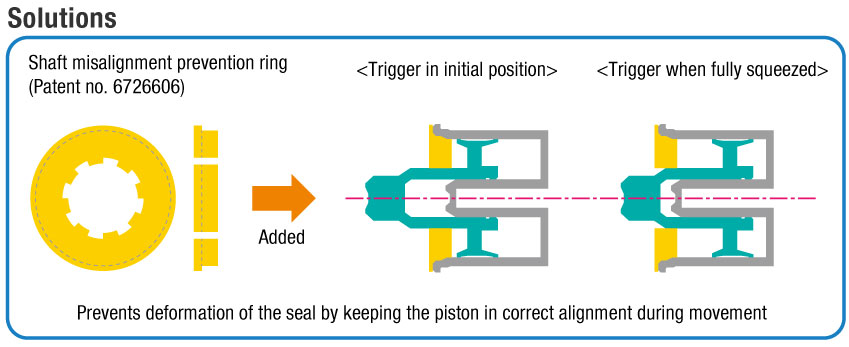

The pistons of existing trigger sprayers did not hold a sufficient volume of detergent fluid to create a long, continuous spray that could apply the detergent to the entire tub. To increase the piston volume, Lion therefore increased the diameter of the piston cylinder. However, with the volume of fluid doubled, the force that had to be applied to the trigger also increased, making it difficult to squeeze. Addressing this problem, we lengthened the trigger, which both provided increased leverage and allowed the user to squeeze with three fingers rather than two. Furthermore, in terms of ergonomics, users naturally apply pressure to the trigger at a diagonal, which can cause the piston to come out of alignment. We addressed this by adding a misalignment prevention ring that keeps the piston centered, preventing unintended motion of the trigger. In this way, Lion’s researchers advance container development through various innovations as they repeatedly identify and solve issues.

Development of Environmentally Friendly Packaging to Realize a Resource-Circulating Society (SOFLAN AromaRich Packaging)

Developing Environmentally Friendly Containers: KireiKirei Hand Soap

Development of Containers to Provide New Options for Daily Life:The LOOK Plus Bath Cleansing Bottle

Related Information