In recent years, the global environment and the SDGs have captured the world’s attention, with interest in the sustainable use of resources and related initiatives heightening. The apparel industry, which has a fundamental connection to laundry, places a particularly large burden on the environment during the clothing manufacturing process, emitting a large amount of carbon dioxide and consuming vast quantities of both water and energy*1. According to a survey by the Ministry of the Environment*2, Japanese households dispose of 496,000 tons of clothing per year, and the disposal process also puts a burden on the environment. To improve the situation, it is important to change how we view the clothing life cycle with an emphasis on using each piece of clothing longer, a change that is necessary not just at the corporate level but at the consumer behavior level. According to Lion’s unique consumer research, the most common reasons for disposing of white clothing were yellowing and darkening, and for black and navy clothing the main cause was fading*3. Lion is addressing the issue of disposal through the development of laundry detergent technology that helps prevent color change and the fading of clothing while also increasing detergency, which is the basic value of detergent.

*1. Ministry of Economy, Trade and Industry’s Emerging State of Fashion Report, 2022

*2. The Japan Research Institute, Limited, Ministry of the Environment, fiscal 2021 research on fashion and the environment, “Fashion and the Environment” survey results

*3. September 2022 online Lion survey (n=2560)

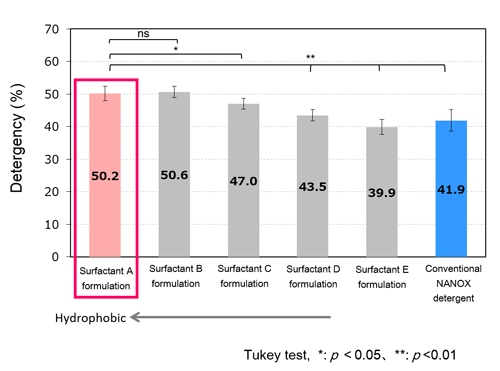

To increase detergency, we focused on sebum and food stains, which consumers find particularly difficult to remove. In this section, we discuss the results of our research on sebum, a cause of yellowing and darkening. Sebum stains may be caused by organic substances, such as proteins and fatty acids, or by inorganic substances and may be a factor in composite stains. Among these, organic substances like solid fats and hydrophobic proteins tend to persist and accumulate in clothing even after laundering, leading to yellowing and darkening. Therefore, we examined detergents with high detergency to remove solid fats and hydrophobic proteins. First, we focused on the properties of solid fats and hydrophobic substances and aimed for high detergency by making the structure of the surfactant, the actual washing ingredient, more hydrophobic. After various experiments, we determined that a detergent combining surfactant A (hereinafter, high-performance surfactant) with higher hydrophobic properties has better detergency than the conventional detergent (NANOX) (Figure 1). By incorporating this high-performance surfactant into our concentrated liquid detergent, which is effective with only a small dosage, we developed a formulation that is less prone to sedimentation and cloudiness, which can also be a source of problems.

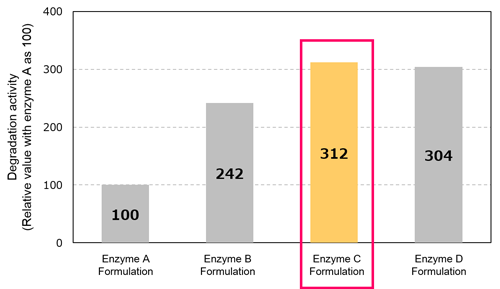

Next, for hydrophobic proteins, we selected enzyme C (hereinafter, high-performance enzyme), which is highly effective at breaking down proteins (Figure 2). This high-performance enzyme is unlikely to degrade for a long time, and is also unlikely to separate. Furthermore, to prevent this high-performance enzyme from being deactivated by the detergent’s other ingredients, we developed a formulation that protects its stability.

To add color change prevention to our detergents, we focused on preventing fading due to repeated washing as well as on controlling re-deposition of soils that leads to darkening and yellowing (contaminants suspended in the washing solution reattaching to fabric). In the following, we begin by introducing the results of our research into preventing fading.

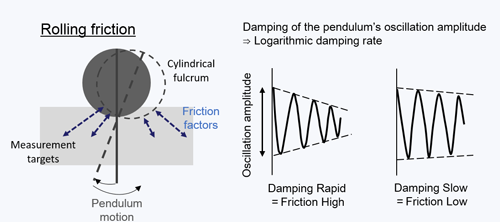

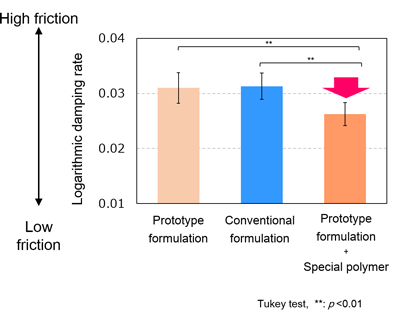

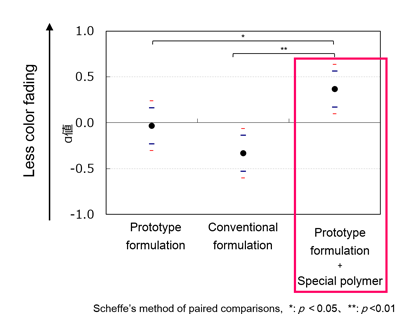

A variety of factors causes clothing to fade, but it is generally understood that it is the action of rubbing against the washing machine surfaces and other clothing that causes fading. Therefore, our aim was to prevent fading by reducing the friction on garments during the washing process. First, we simulated the laundry process using a prototype detergent containing both the high-performance surfactant and the high-performance enzyme as well as a conventional detergent to measure the amount of friction clothing in a liquid washing environment undergoes. Using fiber samples soaked in a cleaning solution, we used a rigid-body pendulum testing apparatus to evaluate the level of friction based on the logarithmic damping rate of the pendulum (Figure 3). The results showed that the friction level remained constant regardless of the detergent used. Therefore, we drew on Lion’s specialized knowledge, adding various base substances to the prototype’s formulation and evaluating the effect of these changes. Our findings indicated that friction can be reduced by adding a specific polymer (hereinafter, special polymer; Figure 4). Black clothing was then washed repeatedly with a detergent containing the special polymer, and a sensory evaluation (Scheffe’s method of paired comparisons) confirmed the fading prevention effect (Figure 5).

We refer to this technology related to cleaning, deodorizing, and color changing prevention as “complete cleaning” and have incorporated it into NANOX one liquid laundry detergent. We are working to extend clothing life through detergent, thereby contributing to the realization of a society in which people can wear their favorite clothes for a long time.

Development of CHARMY Magica Enzyme+ (“Plus”), a dishwashing detergent that uses a proprietary blend of enzymes to break down stubborn oily grime

Development of Cleaning Technologies (Detergency, Deodorizing Power, Protection from Yellowing) for NANOX one

SOFLAN Airis Fabric Softener, Providing a Smooth, Non-Clingy Feel When Wet, Such As After Sweating

Dishwashing Detergent Developed with a Focus on Skin Moisture:CHARMY Awa no Chikara (Power of Suds) Hand Premium

Heyaboshi (Hang-to-Dry Indoors) TOP—Prevents Odors Even During Laundry Use

Related Information