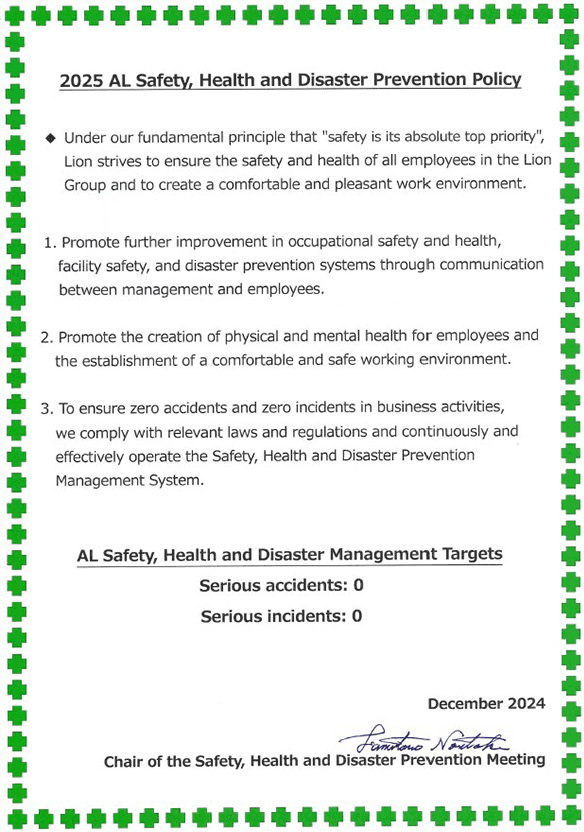

Lion has established the All Lion (AL) Safety, Health and Disaster Prevention Policy based on the shared basic philosophy that safety is its absolute top priority. Accordingly, it strives to ensure the safety and health of all Group employees and to clarify the Group’s overall commitment to establishing a comfortable and pleasant work environment. This philosophy is shared by all Lion Group employees, including those overseas.

The Lion Group has added disaster prevention items to its Occupational Safety and Health Management System (OSHMS)* based on the guidelines of Japan’s Ministry of Health, Labour and Welfare for establishing a unique Safety, Health and Disaster Prevention Management System. Since 2009, we have operated this system at all domestic Group companies, and since 2012 we have included internal audits in our efforts to improve the system’s effectiveness. In addition, since 2014 we have been holding the Safety, Health and Disaster Prevention Meeting (originally launched in 1992 as the Environmental Security Conference). We work in accordance with OSHMS to reduce potential hazards and risks, continuously maintain work environments, create safer workplace environments and build related systems.

* A system for the systematic and organized operation and management of health and safety activities.

The Safety, Health and Disaster Prevention Meeting, chaired by a Lion Group director and executive officer, formulates and deliberates on Company-wide measures to ensure occupational safety (including the work environment, prevention of health problems, and promotion of mental health), facility safety and disaster prevention with the aim of improving conditions at all levels. In 2018, the system was strengthened with the establishment of a dedicated Safety, Health and Disaster Prevention Department to function as the secretariat in this area, and we continue to promote efforts to thoroughly eliminate risk.

Furthermore, Lion Corporation and its domestic Group companies have established their own Safety, Health and Disaster Prevention committees based on the Industrial Safety and Health Act. At each site, employee feedback is considered when working to resolve issues, including problems specific to said site.

We also actively support overseas Group companies in their safety, health and disaster prevention activities from Japan, including sharing the All Lion (AL) Safety Philosophy.

In 2024, the number of fatalities due to work-related and equipment accidents among Group employees in Japan (including temporary employees) was 0.*1

*1 However, there was one accident overseas, involving a contract employee working at the warehouse of one of our consolidated subsidiaries.

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Lion | 0 | 0 | 0 | 0 | 0 |

| Domestic Group companies | 0 | 0 | 0 | 0 | 0 |

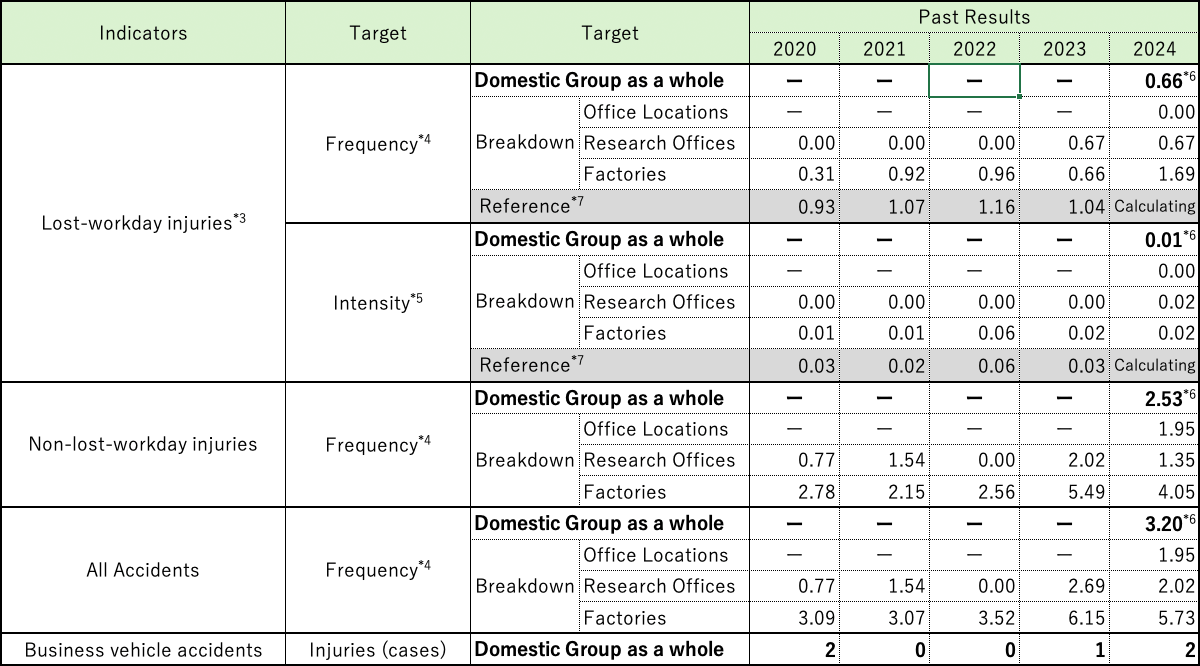

In 2024, there were zero serious accidents among Group employees in Japan (including temporary employees). The number of victims of work-related occupational accidents was 29, of which 6 resulted in lost-workday injuries. Falls were the most common type of accident, accounting for six of the total, and four of these resulted in lost-workday injuries, highlighting that falls are likely to lead to serious injuries.

*2Excludes accidents occuring while commuting

*3Death, lost-workday injury (more than 1 day), loss of bodily function due to non-lost-workday injury

*4Frequency rate = lost-workday injuries (number of victims) / total number of working hours x 1,000,000 hours

*5Intensity rate = number of days lost / total number of working hours x 1,000 hours

*6From 2024, offices will be added to the scope of the calculation, and the scope will be expanded to cover the entire domestic Group.

*7Reference: Ministry of Health, Labour and Welfare Survey of Occupational Accident Trends Chemical Industry

There were zero anomalies*8 in the domestic Group in 2024.

| 2020 | 2021 | 2022 | 2023 | 2024 | |

|---|---|---|---|---|---|

| Lion | 0 | 1 | 0 | 1 | 0 |

| Domestic Group companies | 0 | 0 | 1 | 2 | 0 |

*8Fire, explosion, leakage, etc.

Safety audits are systematically conducted at domestic Group production plants under the supervision of the chairperson of the Safety, Health and Disaster Prevention Meeting. To reduce the risk of accidents and disasters at factories, on-site audits are conducted to ensure that safety, health and disaster prevention activities are being implemented and, from an objective standpoint, that related standards are being maintained and improved.

In 2024, top safety audits were undertaken at three factories.*

* Osaka Plant, Oleochemicals Division of Lion Chemical Corporation, and Yokkaichi Plant of Lion Specialty Chemicals Co..

The secretariat of the Safety, Health and Disaster Prevention Meeting issues a “disaster bulletin” to all employees regarding occupational accidents that have occurred within the Group in Japan, in order to avert the risk of similar accidents occurring at each business site as well as to ensure that each and every employee stays on the alert against occupational accidents.

In recent years, falls have perennially been the most frequent cause of accidents, therefore, we will continue to promote activities focusing on their prevention.

The results of investigations of equipment accidents inform the implementation of equivalent improvements in similar areas at all domestic Group production plants. For example, learning from recent equipment leakage accidents, all of the Group’s production plants have conducted inspections of outdoor tanks used for hazardous material and oil storage, and reviewed their Equipment maintenance plans. Furthermore, we are considering the introduction of a new non-destructive inspection method to preemptively assess the risk of leakage due to age-related deterioration. We will continue to enhance the operation of the change management* process to further improve equipment safety technology and reduce accident risks in the medium and long term.

* Management activities to prevent risks associated with changes in equipment and operating conditions

All domestic Group production plants conduct joint disaster drills with local public fire departments to prepare for large-scale disasters at production plants and actively strengthen cooperation with local communities in case of emergency. In October 2024, the Kagawa Prefecture Petroleum Complex Comprehensive Disaster Drill* was conducted at the Oleochemical Plant of Lion Chemical Corporation as the lead company.

* Participating organizations and companies: Shikoku Regional Development Bureau, Kagawa Prefectural Emergency Management and General Affairs Bureau, Sakaide City Fire Department, Takamatsu Coast Guard, Sakaide Coast Guard Station, Japanese Red Cross Society, Banshu District Special Disaster Prevention Council (Cosmo Oil Co., Ltd., Shikoku Electric Power Company, Mitsubishi Chemical Corporation, Kawasaki Heavy Industries, Ltd., YKK AP Inc, Lion Chemical Corporation)

The domestic Group has created detailed manuals and plans of action on how to respond in the event of a natural disaster. In particular, we consider large-scale earthquakes, heavy rainfall from linear precipitation belts, and other natural disasters to be corporate risks. Therefore, in addition to disaster drills conducted by each business site that specify detailed response details and action standards according to the scale and damage of the disaster, we conduct Company-wide joint disaster drills to promote activities aimed at risk mitigation.

In addition, to accommodate diversifying work styles, we have established a disaster preparedness system that integrates in-person and remote locations in preparation for large-scale natural disasters.

Anticipating an increase in the frequency and severity of natural disasters and the further diversification of work styles, we will further upgrade our disaster response system. At the same time, through safety confirmation drills and lifesaving courses, etc., we will also continue to strengthen the emergency response efforts undertaken by each employee as well as our disaster prevention activities that contribute to local communities.

To prevent occupational accidents, we must further enhance our safety management system and heighten every members’ occupational safety awareness. We systematically implement safety awareness training via Company-wide internal e-learning and safety training at each business site. In 2024, there was a 100% implementation rate of safety education and training in each department, and 97.3% of all employees participated in the Company-wide internal e-learning and safety training.

| 2023 | 2024 | |

|---|---|---|

| Participants | 4,373 | 4,256 |

| Participation Rate | 96.2% | 97.3% |

Under a 33-year program to raise awareness of the importance of safety among all domestic Group employees, the Lion Group has designated June 26 of each year as “Lion Safety Day.” Highlighting the event, a message and lecture on the importance of safety are delivered, respectively, by the president and the chairperson of the Safety, Health and Disaster Prevention Meeting and broadcast to all production plants throughout the entire domestic Lion Group during a Company-wide morning assembly. In conjunction with Lion Safety Day, we are also developing various safety awareness initiatives, such as safety slogans and safety awareness surveys for all domestic Group employees.

The Lion Group provides ongoing support to overseas Group companies based on their circumstances and strives to enhance their safety, health and disaster prevention systems.

In 2024, representatives from Lion visited three overseas production plants (Vietnam, Indonesia and Malaysia) and two overseas offices (Hong Kong and Singapore) to identify safety risks and improve areas of concern by checking the safety management situation in each country. In addition, they held discussions with local employees aimed at raising safety awareness and improving workplace accident prevention efforts.

We also supported the provision of safety guidance by an outside organization to an overseas production plant (Thailand), taking advantage of the Asia Occupational Safety and Health SAKURA Project, a project subsidized by the Ministry of Health, Labour and Welfare.