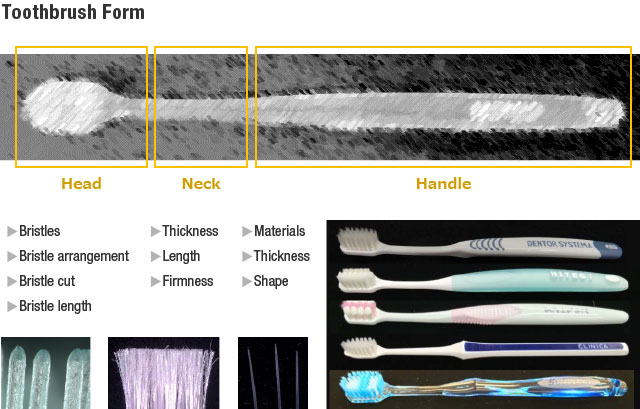

A toothbrush consists of three basic parts—the head, which supports and the brush and in which bristles are embedded, the handle, which the user holds, and the neck, connecting the head and handle. The materials, thickness and length of each of these parts varies by product. In toothbrush R&D, to create new products, researchers apply past insights and expertise as well as their own ideas, in line with specific product concepts, to determine the materials and shapes for each part, from brush to handle, along the way creating and evaluating numerous prototypes. The process of determining product specifications is extremely time-intensive, as a prototype must be made to reflect every minute change in each parameter, such as shape, thickness and length. To significantly reduce the time taken by this process, Lion uses artificial intelligence (AI) in its toothbrush R&D.

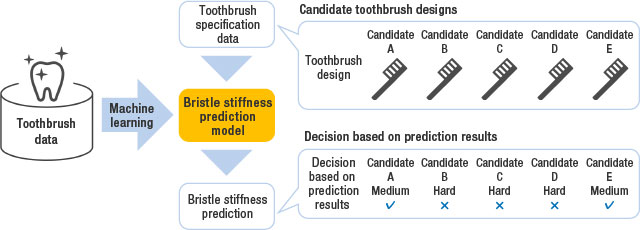

For example, we use AI to predict quality factors related to the effective bristle firmness of toothbrush designs, which are the basis for the “Hard,” “Medium” or “Soft” specifications. Using this process, we are able to judge if a design’s specifications conform to the product concept and Japanese Industrial Standards (JIS) without having to create an actual prototype. While prototypes must still be created for final evaluations, the overall process, which used to take several days, has been shortened to around an hour, improving development efficiency. In addition, the use of AI allows us to capture in data something of the experience and intuition of seasoned researchers, which have previously proved difficult to pass on to new staff, facilitating the transmission of know-how to junior researchers and human resource development.