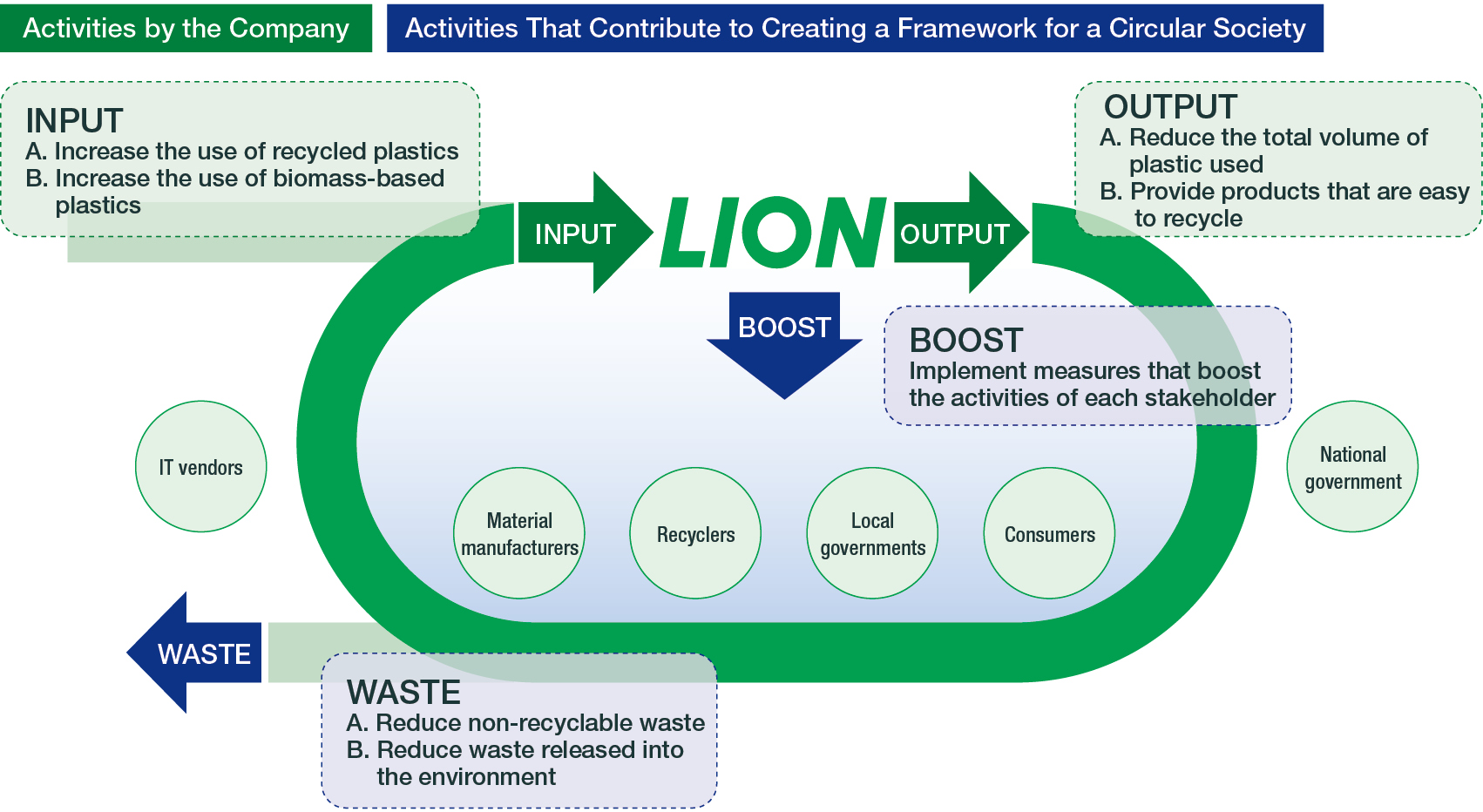

The Lion Group has divided its activities aimed at realizing a resource-circulating society into four categories, namely, input and output (encompassing business activities with direct impacts) and waste and boost (which are collaborative activities with stakeholders that contribute to the circulation of resources). We formulate and implement measures in line with these categories.

The Lion Group proactively uses recycled plastic in products and containers. Our liquid laundry detergent bottles and toothbrush blister packs are made with plastic recycled from disposable beverage bottles (PET bottles) and other sources.

| Material | Category | Product name | Application |

|---|---|---|---|

| Polyethylene terephthalate PET (PCR) |

Dishwashing detergent | CHARMY Magica* | Bottle |

| Liquid laundry detergent | TOP Clear Liquid Kaori Tsuzuku (Long-Lasting Frangrance) TOP Sweet Harmony | Refill pack | |

| Toothbrush | Clinica PRO Toothbrush Rubber Head | Blister dome packaging | |

| Polyethylene PE (PCR) |

Fabric softener | SOFLAN Aroma Rich SOFLAN Premium Deodorizer | Bottle |

* Partial usage

Recycled Material Usage at Overseas Group Companies

Our overseas group companies are also expanding the use of recycled plastics in products, containers and packaging, and working to reduce the usage of petrochemical-derived materials. As an example, Lion Corporation (Korea) has adopted recycled plastics for the main bottle of “Ai-Kekute*”

* 『Ai-Kekute(literally, Oh! Clean!) is a hand soap brand marketed by LCK.

| Country | Material | Category | Product name | Application |

|---|---|---|---|---|

| South Korea | Polyethylene PE (PCR) |

Hand soap | Ai-Kekute* | Bottle |

| Thailand | Polyethylene terephthalate PET (PCR) |

Toothbrush | SYSTEMA*, SALZ*, KODOMO* |

Blister dome packaging |

* Partial usage

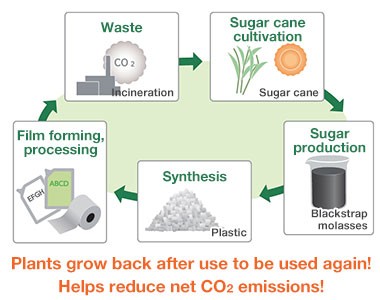

The Lion Group is promoting the use of containers and packaging made with biomass plastic. Using renewable resources helps to reduce dependence on fossil materials, thereby contributing to the realization of a sustainable society. By utilizing waste as an energy source, we are able to reduce waste and revitalize local economies as well as support the shift towards carbon neutrality.

| Material | Category | Product name | Application |

|---|---|---|---|

| Polyethylene terephthalate PET |

Liquid laundry detergent | NANOX one | Bottle |

| Body wash | Hadakara Body Soap | ||

| Dental rinse | NONIO Mouthwash NONIO Plus Whitening Dental Rinse CLINICA Quick Wash SYSTEMA EX Dental Rinse OCH TUNE Mouthwash , etc. |

||

| Toothpaste | CLINICA Advantage Toothpaste, etc. | Tube | |

| Polyethylene PE |

Liquid laundry detergent | NANOX one series | Refill pack |

| Bleach | Bright STRONG | ||

| Hand soap | KireiKirei Medicated Hand Conditioning Soap* | ||

| Pocket Size KireiKirei Medicated Foaming Hand Soap | External bag | ||

| Hand sanitizer | KireiKirei Medicated Hand Sanitizing Gel Plus | ||

| Antiperspirant and deodorant | Ban Sweat-Blocking Roll-On and Stick |

* Partial usage

Products that meet the Japan Organics Recycling Association’s requirements for certification are allowed to carry the Biomass Mark. For details, please visit the website of the Japan Organics Recycling Association [Japanese].

List of Lion's certified biomass products(The Japan Organics Recycling Association) [Japanese].

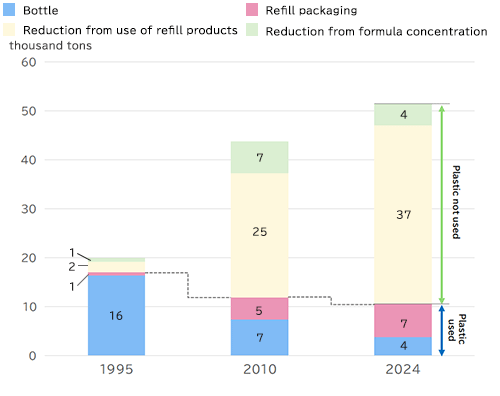

The Lion Group’s plastic bottles can be refilled and reused. Because refill packs are constructed from film, they are produced using far less material than conventional product bottles. For laundry products such as laundry detergent, the production of a refill pack uses one-fourth* the volume of material used in making a product bottle. Furthermore, they take up less space after use, so help reduce the volume of household waste. We are also working on creating more refillable products, expanding the categories covered to include products like mouthwash. In these ways, we are reducing the plastic we use.

To reduce product and container materials, the Lion Group complies with “The Lion Eco-Standard”, which is designed to evaluate products over their entire lifecycles by examining each life cycle stage, from raw material procurement to distribution and disposal. We are increasing the concentration of such products as laundry detergents, fabric softeners and dishwashing detergents so that their containers can be made more compact while using sophisticated design technology to reduce container weight.

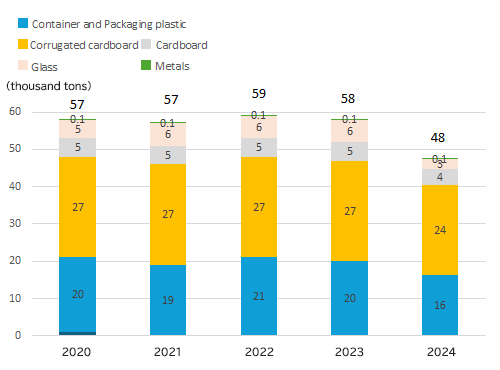

Lion’s Container and Packaging Material Usage (Domestic Household Products)

Lion’s Use of Plastic for Packaging and Reduction Effects

With an eye to cutting recycling costs and ensuring high-quality recycled materials, the Lion Group is striving to improving the recyclability of its products In addition, Lion is developing technologies aimed at realizing products and containers that are easier to recycle.

Commercializing Products with Better Recyclability

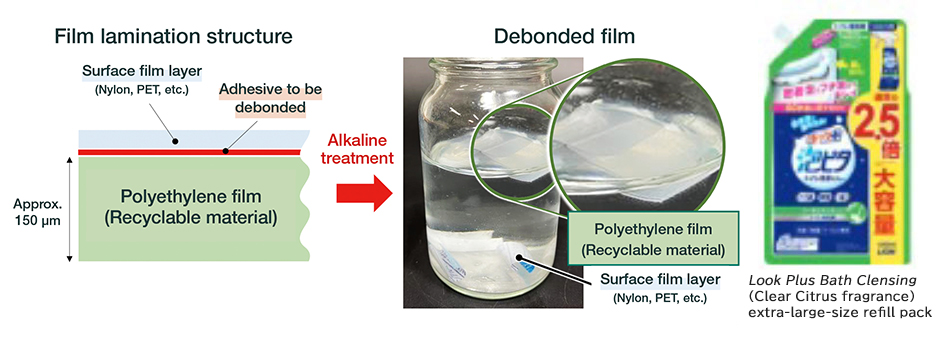

Many refill packs—the primary packaging used for such refillable products as detergent—are made of a multi-layered plastic film that itself is difficult to recycle, so most of them are incinerated. To address this, Lion collaborated with TOYO INK CO., LTD. to create peelable recycling technology that makes these types of refill packs easier to recycle. In November 2024, we launched a limited-edition run of LOOK Plus Bath Cleansing (Clear Citrus fragrance) in a large-size refill pack created using this new technology. We expect to see recycling progress because this technology enables these types of composite materials to be separated into individual substances with high levels of purity.

Efforts are made to ensure that the products offered by the Group are recycled in an appropriate manner after use. In addition, we conduct various activities to promote the establishment of an advanced recycling system throughout society.

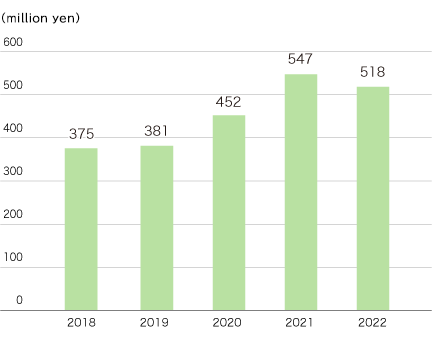

Being a specified business entity operating under the Containers and Packaging Recycling System, we contribute recycling operation contract fees. For the most recent status of operations under this system, please visit the Japan Containers and Packaging Recycling Association website.

The Japan Containers and Packaging Recycling AssociationAmount Contributed to The Japan Containers and Packaging Recycling

Association (After payment)

Aiming to achieve a continuous cycle of plastic use in society, and to go beyond recycling in existing social infrastructures to higher quality recycling, Lion is conducting pilot testing for the recycling of used products and containers and packaging in cooperation with household product manufacturers, recyclers, retailers and local governments.

| Recyclable items | Activity name | Area | Main partners |

|---|---|---|---|

| Toothbrushes | Toothbrush recycling | Over 1,600 locations nationwide | TerraCycle |

| Joint municipal toothbrush recycling | Sumida-ku, Itabashi-ku, Taito-ku, Edogawa-ku and Akashi-shi | Takaroku Corporation | |

| Toothbrush recycling at educational institutions | A number of private nursery schools in Saitama Prefecture | Saitama Private Kindergarten Federation Community Net Inc. Takaroku Corporation |

|

| Refill products | RecyCreation | Ito-Yokado’s Hikifune Store Welcia Pharmacy stores (parts of Tokyo and Saitama Prefecture) |

Kao Ito-Yokado Welcia Pharmacy Store Hamakyorex |

| Kobe Plastic Next: Joining Forces to Recycle Refill Packs |

75 stores and 27 other facilities in Kobe City | Kobe City Household product manufacturers Distributors 12 recycling companies |

|

| Bottles | Making New Bottles from Used Bottles Collaboration among consumers, local governments, and companies Bottle Recycling Project for Everyone | Tokyo | Unilever Japan Kao Corporation Veolia Japan G.K. digglue Inc. |

As of May 31, 2025

Promoting Circulation of Plastic Container and Packaging Resources through Partnerships

Kao Corporation and Lion are reaching out beyond their corporate groups in an effort to recycle plastic refill containers and packaging (film packaging), aiming to realize a resource-circulating society.

To accelerate the adoption of recycling, building basic systems for resource collection and developing recycling technologies are indispensable. At the same time, it is necessary to change mindsets across society in cooperation with stakeholders, including consumers, with regard to, for example, sorting plastic packaging after product use.

We work together to raise awareness about the collection system, recycled materials, container design quality, uses for recycled materials and consumer participation. We have set up special collection boxes at the Ito-Yokado Hikifune store (Sumida-ku, Tokyo) and a number of Welcia Pharmacy locations (Tokyo and some parts of Saitama prefecture) to collect used refill packs. We request that those participating in this initiative follow the rules for collection.

Video on how to wash used refill packs (Japanese)

These RecyCreation activities, along with related companies, have received the following commendations.

News Release: Kao and Lion Awarded the New Selection Committee Chairman’s Commendation in the Good Practices of Consumer-Oriented Management Awards [Japanse] News Release: Lion, Kao, Ito-Yokado, Welcia Pharmacy, and Hamakyorex Jointly Receive the Minister of Environment Award in the 6th Japan Open Innovation Prize [Japanese]Demonstration of the Horizontal Recycling of Refill Packs

In May 2023, we launched a recycled plastic version of the XXL refill pack for Lion’s TOP SUPER NANOX For Odors, a highly concentrated liquid laundry detergent. The materials used to create the refill pack consisted in part of recycled materials from used refill packs that had been collected. (Not available at this time.)

This packaging incorporates 9% recycled materials derived from factory waste and 1% derived from recycled consumer products.

This refill pack has won the following awards together with Lion’s collaborative partners:

President of Japan Packaging Institute Award, Japan Packaging Contest 2023, Japan Packaging Institute 48th (2024) Kinoshita Award, Research and Development Category, Japan Packaging Institute 2024 WorldStar Global Packaging Award, World Packaging Organisation

About Toothbrush Recycling

As a toothbrush manufacturer, we implement the following collection programs for used toothbrushes:

Through these activities, we aim to increase the number of toothbrushes collected and improve awareness in society that old toothbrushes can be a useful resource.

Toothbrush Recycling Program [Japanese]The Group has a wide array of frameworks in place and promotes activities to realize a resource-circulating society, a goal it cannot achieve on its own.

| Name of Group or Organization | Title | Main Goal of Activities |

|---|---|---|

| Japan Clean Ocean Material Alliance | CLOMA | Resolving problems regarding plastic waste in the ocean |

| Circular Partners〔Japanese〕 | CPs | Promoting collaboration of industry, government and academia to create a circular economy |

| Plastic Packaging Recycling Council〔Japanese〕 | PPRC | Promoting recycling of plastic packaging by collaborating with residents and local governments |

| Ecosystem Society Agency〔Japanese〕 | ESA | Working with local governments and businesses to generate social value |

We have published a development case for an environmentally conscious package precedent search system known as “Plastic and Search” that the Plastic Packaging Recycling Council manages.

Environmentally-Conscious Package Precedent Search System “Plastic and Search” 〔Japanese〕

“Platto Search,” Our company’s page in 2024〔Japanese〕

Lion’s four domestic plants all achieved zero waste emissions*1 in 2002. All of Lion’s operating sites,*2 including research institutes and offices, achieved zero waste emissions in 2017.

*1 Our definition:The waste recycling ratio is 99% or more, excluding recycling residues

*2 Chiba Plant, Odawara Plant, Osaka Plant, Akashi Plant, Hirai Office Site, Sapporo Office, Sendai Office, Headquarter, Nagoya Office, Osaka Office, Fukuoka Office, Lion Chemical Co., Ltd. Fine Chemical Production Site, Lion Chemical Co., Ltd. Oleochemical Production Site, Lion Specialty Chemicals Co., Ltd. Yokkaichi Plant, Lion Specialty Chemicals Co., Ltd. Ono Plant

ESG Data EnvironmentWe will continue to advance initiatives to reduce waste going forward.

Maintenance and management information based on the Waste Management and Public Cleansing Law (Article 15-2-3, Paragraph 2) is made public.