To advance responsible procurement activities, each year the Lion Group asks that the materials manufacturers and production contractors (suppliers) it works with implement self-checks based on the Lion Group Supplier CSR Guidelines. In this way, we are promoting the creation of frameworks throughout the supply chain to avoid risk related to human rights, labor practices, the environment, fair operating practices, consumer issues and compliance.

Since 2014, we have moved the self-checks entirely online, enabling suppliers to respond more efficiently. We also provide suppliers with feedback based on the self-check results. The result of these efforts is a system that continuously advances CSR procurement, through which we aim for a 100% response rate every year.

In 2024, Lion Corporation (Korea) requested self-checks from its 89 suppliers, achieving a response rate of 84%. Lion Daily Necessities Chemicals (Qingdao) Co., Ltd. (China) requested self-checks from its 40 suppliers, achieving a response rate of 98%. Southern Lion Sdn. Bhd. requested self-checks from its 51 suppliers, achieving a response rate of 45%. Lion Corporation (Thailand) Ltd. requested self-checks from its 53 suppliers, achieving a response rate of 91%.

Additionally, self-checks*2 were also conducted by 68 trading partners of Lion Engineering Co., a domestic Group company, achieving a response rate of 93%.

We will continue to promote sustainability initiatives with our suppliers in the countries where we have all of our Group’s production division plants.

*1The Lion Group Supplier CSR Guidelines comprise 21 guidelines under the five categories (Human Rights/Labor Practices, The Environment, Fair Operating Practices, Consumer Issues, Compliance)

*2Lion Engineering Co., Ltd.’s version of the self-check includes the addition of “Confrontation with antisocial entities: Cut off relations with antisocial entities and reject any unreasonable demands” to item 21.

| 2005 | Instituted the Basic Policy Regarding Purchasing and implemented appropriate procurement of raw materials and products. |

|---|---|

| 2008 | Established the Procurement Principles, which clarify our social and environmental considerations. Conducted a questionnaire survey for domestic and overseas raw material manufacturers and production contractors about their corporate activities regarding legal compliance, product service quality and safety, environmental considerations, labor practices and human rights, and fair trade. |

| 2013 | Amended the Procurement Principles and clarified our stance of considering legal compliance, environmental conservation and respect for human rights when selecting suppliers. Instituted the Lion Group Supplier CSR Guidelines, which specify the sustainability initiatives we expect from raw material manufacturers and production contractors and asked our suppliers to conduct self-checks of their sustainability initiatives. |

| 2014 | Introduced an online self-check system. |

| 2018 | Lion Corporation (Korea) requested self-checks from its suppliers, expanding the number of countries in which the Group implements self-checks. |

| 2019 |

|

| 2020 | Overseas Group company Lion Daily Necessities Chemicals (Qingdao) Co., Ltd. requested self-checks from its suppliers. |

| 2021 | Domestic Group company Lion Engineering Co., Ltd. requested self-checks from its suppliers. |

| 2022 | Overseas Group company Southern Lion Sdn. Bhd. requested self-checks from its suppliers. |

| 2023 | Overseas Group company Lion Corporation (Thailand) Ltd. requested self-checks from its suppliers. |

| 2024 | Providing suppliers with reference materials to help improve CSR activities at the time of feedback. Examples of reference materials

|

The Lion Group does business with suppliers who have implemented self-checks based on the Lion Group Supplier CSR Guidelines.

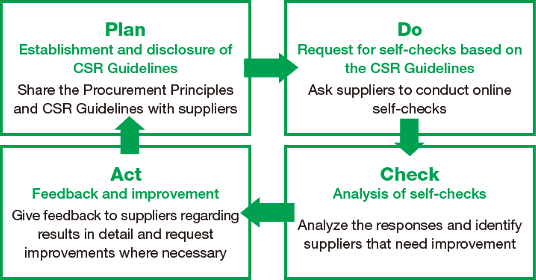

PDCA Cycle for Self-Checks

In order to ensure that our suppliers understand the importance of addressing sustainability-related issues, we include a section explaining the situation surrounding sustainability in our self-check request form. The self-check employs a three-step checking standard for each initiative and a detailed glossary.

| Primary Suppliers | Response Rate | |

|---|---|---|

| 2020 | 574 | 100% |

| 2021 | 502 | 100% |

| 2022 | 474 | 96% |

| 2023 | 436 | 96% |

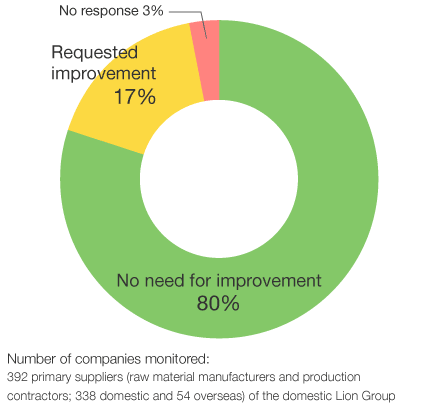

| 2024 | 392 | 97% |

The Lion Group considers suppliers from whom it purchases substantial amounts of raw materials and suppliers that cannot be readily replaced to be key suppliers. We monitor the sustainability initiatives of key suppliers on an ongoing basis. Specifically, we define key suppliers as the top 30 companies (on a purchase price basis) serving each of the three divisions of the Purchasing Headquarters (Raw Material Department, Packaging Material Department, Finished Product Department), for a total of 90 companies (total includes five Group companies).

| Number of key suppliers | Percentage of key suppliers among primary suppliers | Portion of purchasing that is from key suppliers (monetary basis, among all primary suppliers) | |

|---|---|---|---|

| 2020 | 90 | 15.7% | 89% |

| 2021 | 90 | 17.9% | 89% |

| 2022 | 90 | 17.9% | 89% |

| 2023 | 90 | 19.3% | 89% |

| 2024 | 90 | 25.6% | 92% |

After receiving the self-checks, the Lion Group confirms whether or not suppliers are meeting the standards it has set for its key sustainability items. Suppliers with low scores are designated as high-risk suppliers. In 2024, there were no high-risk suppliers.

Before doing business with a new supplier, Lion requires the company to perform a self-check based on the Lion Group Supplier CSR Guidelines to confirm that the company meets the standards it has set for its key sustainability items.

Headquartered in the United Kingdom, Sedex is a not-for-profit organization that provides the world’s largest platform for managing and sharing ethical supply chain data, with the aim of establishing ethical and responsible business practices in global supply chains. The Lion Group joined Sedex as an AB member at the end of 2019 in order to further reduce social and environmental risk in its purchasing. We encourage our suppliers to join Sedex to reduce the burden of self-checks and request that they use the platform provided by Sedex to submit their annual self-check responses. Of Lion’s 90 key suppliers, 43 are using the Sedex platform (as of May 30, 2025). In addition, after the close of 2024, the Company has initiated a high-risk supplier response, requesting corrective action responses from seven suppliers whose management control scores and SMETA audit remediation responses did not meet its standards. All suppliers have since met the Company’s standards, with improvements in SAQ updates and SMETA audit findings. Going forward, we will continue to reinforce and enhance supplier management and risk management.

Lion provides sustainable procurement training to every purchasing department employee who is involved in buying. We also hold study groups to help employees obtain certification under the Certified Procurement Professional (CPP) system offered by the Japan Management Association.* Participants not only learn buying operation management and gain practical knowledge, they learn about the importance of procurement that takes into account the environment, ethics, safety and hygiene, human rights and other such factors as well as about working with suppliers.

When selecting suppliers and setting pricing and other terms, we always enter into agreements through negotiations rooted in fairness and transparency. We thoroughly enforce compliance with the Act against Delay in Payment of Subcontract Proceeds, Etc. to Subcontractors through such means as training for Purchasing Headquarters employees.

In response to growing calls for CSR procurement, going forward, we will advance human resource development, including proactively sending employees to seminars related to purchasing and procurement.

* CPP: A qualification for persons involved in corporate purchasing and procurement indicating that the holder has acquired specialized knowledge in the field of purchasing and procurement.

CPP qualification website [Japanese]