The Lion Group is working to reduce water use in line with the LION Eco Challenge 2050, a set of long-term environmental objectives formulated in 2019 with the aim of realizing environmental sustainability. In 2019, Lion began calculating water use throughout the supply chain in order to understand water use throughout product life cycles—from raw material procurement to production, transport, use and disposal. Total water use throughout the life cycles of Lion’s products in 2024 was approximately 2.1 billion m3.

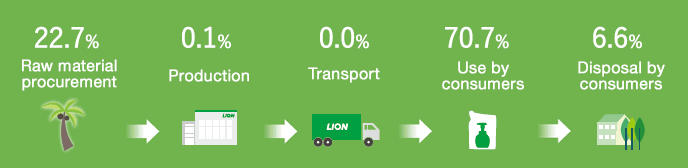

Breakdown of Water Use over the Life Cycles of Lion Products*

* Scope: Lion and domestic and overseas consolidated subsidiaries, January–December 2024.

At 74.9%, the product life cycle stage that accounted for the largest portion of total water use in 2024 was use by consumers. This is because many Lion Group products, such as laundry detergents, are used with water for washing. The Lion Group will continue to work with consumers to reduce water use throughout product life cycles by providing environmentally friendly products and services that help save water and promoting the formation of environmentally friendly habits.

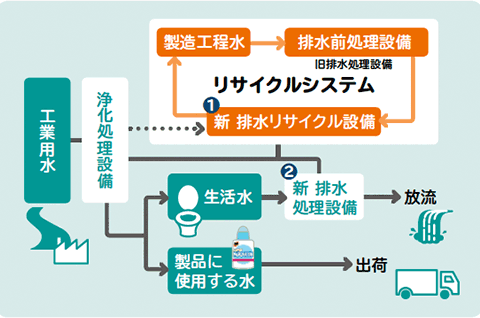

The Lion Group continuously monitors water usage (water withdrawal) and wastewater discharge in its business activities as it strives to alleviate environmental impact and reduce water usage through recycling. We have been implementing ongoing measures to reduce water used in cleaning processes. As part of these efforts, we have been operating industrial wastewater recycling facilities at the Chiba Plant since 2016.

Identification and Evaluation of Water-Stressed Regions

The Group performs water stress evaluations for all its business locations using Aqueduct, a set of tools developed and announced by the World Resources Institute. We consider the regions in which our business locations are located to be water-stressed if their baseline water stress (one of the indicators outlined by Aqueduct) is designated “extremely high.” The results of these evaluations showed that the Group has four-locations in water-stressed regions, and their water intake was 2% of the Group’s total.

The Lion Group manufactures and sells products that are closely tied to water usage. Moreover, Lion’s plants use a great deal of water in manufacturing processes to clean facilities and in heating and cooling equipment. Recycling wastewater after use can thus produce a significant water-saving effect. To this end, Lion introduced a wastewater recycling system at the Chiba Plant—which uses the most water among Lion’s plants—in 2016 that has been in continuous use since installation. The greatest feature of this system was the adoption of new wastewater recycling facilities (①). Thanks to these facilities, we are now able to recycle wastewater from production processes that was previously discharged into the environment. Furthermore, we installed new wastewater treatment facilities (②) that enable greater purification of water from employee sanitary facilities and cleaning facilities than was previously possible, better removing nitrogen, which is a source of marine eutrophication.

In 2024, we conserved about 200,000 tons of water annually compared to 2010. That amount is equivalent to about-24% of the total water usage of all domestic operating sites in 2024.

The Chiba Plant was the first household product factory in Japan to recycle wastewater. In 2017, the plant received the New Technology Encouragement Award*1 from the Japan Society on Water Environment and the Responsible Care Award*2 from the Japan Chemical Industry Association.

*1In June 2017, the development of the Chiba Plant’s wastewater recycling system was recognized with the New Technology Encouragement Award from the Japan Society on Water Environment, Japan’s largest academic society related to protecting the aquatic environment. This award is given for research related to aquatic environments or to individuals or organizations that have devised innovative, promising aquatic environment technologies from the perspective of social contribution.

The Japan Society on Water Environment New Technology Encouragement Award [Japanese]*2In May 2017, the Chiba Plant received the 11th Responsible Care Award from the Japan Chemical Industry Association for its initiatives to protect the aquatic environment and contribute to the local community. Since the start of its operations, the Chiba Plant has continuously implemented activities to protect the aquatic environment.

Lion’s Responsible Care ActivitiesThe Lion Group is working to reduce water usage throughout the life cycles of its products. To reduce water usage during product use—the product life cycle stage that accounts for the greatest portion of water use—we provide environmentally friendly products that help save water. For example, since 2020, all Lion liquid laundry detergents can be used with just one rinse cycle. In April 2025, we also developed and marketed Acron Yasashisa Premium, a zero-rinse laundry detergent.

Under LION Eco Challenge 2050, a set of long-term environmental objectives, the Group set the target of reducing water usage 30% per unit of net sales across product life cycles by 2030 in comparison with 2017 levels. In 2024, life cycle water usage was reduced 22% per unit of net sales in comparison with 2017.

Going forward, we will continue to develop products that help reduce water usage during product use and promote environmentally friendly habits as we strive to reduce the environmental impact of households.

Breakdown of Water Use over the Life Cycles of Lion ProductsAcron Yasashisa Premium

It is a fashionable clothing detergent with softening ingredients. A special polymer with proprietary technology supports the action of cleaning ingredients. Even with a small number of cleaning ingredients, dirt and odors can be removed cleanly, and it can be used with 0 rinses.

(This product’s effects on skin have been tested under the supervision of dermatologists.)

CHARMY Magica Quick Dry + (“Plus”) Antibacterial

These nano-cleansing dishwashing detergents make stubborn grease slide off dishes like water, helping save time and water when washing up.

Ofuro no LOOK (Bath cleaner)

Bathroom cleaner compounded with quick-rinsing component to clean stains with fast defoaming action.

Look Plus Bath Antimold Fogger

A fumigation-type fungicide that employs a silver-ion fog to kill black mold spores throughout the bathroom, helping prevent the growth of mold and reducing water used during post- mold removal and cleansing rinses.

Soft in 1 Shampoo

A two-in-one conditioning shampoo that leaves hair feeling smooth and moisturized without an extra conditioning and rinse stage.

Lion sells NANOX one and CHARMY Magica through Lion Corporation (Singapore) Pte Ltd, Lion Daily Necessities Chemicals (Qingdao) Co., Ltd. and Lion Corporation (Hong Kong) Ltd. and Lion Home Products (Taiwan) Co., Ltd., helping to save water.